Manufacturing in Mexico is a great idea for industries that are growing at an accelerated rate and selling in the USA or Canada. It has been attractive worldwide for a time now and there is an explanation for this.

Why manufacturing in Mexico will be a competitive advantage for you?

- Manufacturing in Mexico allows for proximity to markets in the USA, Canada, and Latin America.

- Same timezone communication with the North American market.

- Quality culture: ISO, AS, NADCAP, and other international quality standards.

- Technical training support.

- Skilled and affordable workforce.

- Supply Chain Integration.

- Tax incentives for manufacturing in Mexico: no VAT.

- Tariffs savings due to Mexico’s Free Trade Agreements with various countries.

- Well-developed “soft landing” culture to help international companies start manufacturing in Mexico.

- Legal certainty for intellectual property.

Advantages of Manufacturing in Mexico

Manufacturing in Mexico will give a combination of advantages not found anywhere in the world: two coastal frontiers to export or import, a wide and productive labor force, and integration with the USA logistics and customs system.

Something else to consider is the workweek in Mexico, the United States has a 40-hour workweek and Mexico has a 48-hour workweek, this will increase your production output by 16%, so manufacturing in Mexico just by hourly work, can increase your profits.

Wages in Mexico are significantly less than in the United States, according to a KPMG study. Mexico has remained stable in its labor hourly rate.

Manufacturing in Mexico has the advantage of proximity to the North American markets and the USMCA treaty (T-MEC in Spanish), which also reduces costs and could make any commercial business more profitable.

For global manufacturing companies looking to reduce costs, there is no location in the world that is closer to the United States than Mexico, besides Canada. Location factors are important to manufacturers planning for transportation, logistics, and time-in-transit costs to get their products to the market.

Compared to overseas locations like China where transportation can take nearly 30 days, or more, to arrive in the USA or Mexico.

Besides that, the shipping costs are increasing, and we are looking at a bottleneck in global transportation. It’s time to widen our vision.

One of the most important advantages of manufacturing in Mexico is that it is the country with the most trade agreements and the interesting IMMEX program, which increases manufacturing in Mexico with duty-free raw materials and machinery.

What is IMMEX?

The IMMEX program allows companies with VAT Certification to defer the 16% VAT on the temporarily imported raw materials and components to Mexico as long as they are transformed into finished goods or processed, and then exported within 18 months.

Which are the requirements for IMMEX?

Here are some of the requirements to get into the IMMEX program:

- Be a legal entity in Mexico with the obligation to pay income tax (ISR).

- Export US$500,000 in a one-year period.

- Have the goods and services in the registered & approved addresses.

Industries and big companies Manufacturing in Mexico

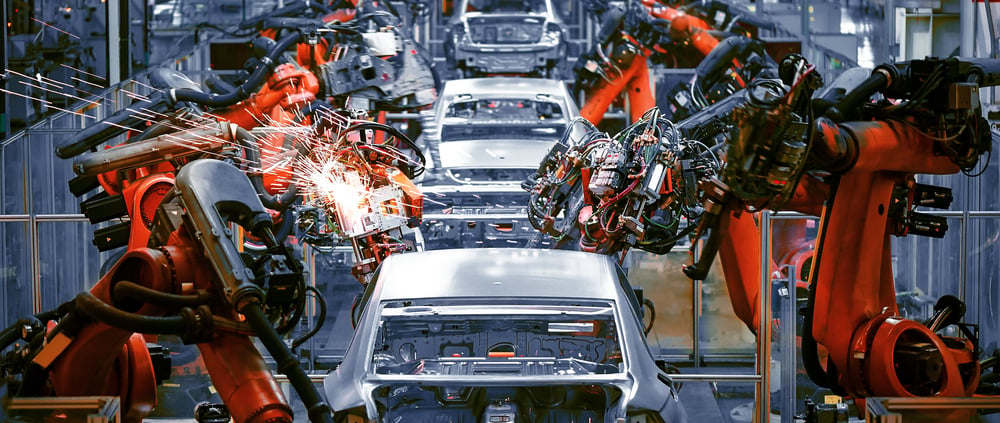

Major global manufacturers are very interested in Mexico. Mexico’s principal manufacturing industries are aerospace, automotive, auto parts, electronics, medical devices, furniture, metal mechanical, and plastic injection molding.

Major industries in Mexico have attracted global manufacturing companies such as Volkswagen, GM, Bombardier, Bose, Eaton, and other world-class corporations by proving the technical skills and capabilities to compete not only in North America but on the world stage as well.

In Tijuana alone, industrial supply demand totals $11B USD annually, with a majority in electronics, medical products, automotive, aerospace, and defense.

Product sourcing in Mexico doesn’t have to be hard. Talk with a Mexico Sourcing Agent and learn more about your industry.

Read more about Manufacturing in Mexico in our product sourcing section.